Product Variants & Series Offered by Placka Instruments Pvt. Ltd.

Placka Instruments offers a comprehensive range of pneumatic air treatment units tailored to diverse industrial needs, including:

Filter + Regulator + Lubricator: The complete all-in-one air preparation solution combining filtration, pressure regulation, and lubrication in a single compact unit for optimal pneumatic system performance.

Filter Regulator + Lubricator: Integrated units combining air filtration and pressure regulation with added lubrication, balancing efficient air quality management and tool protection.

Filter & Regulator: Standalone filter and pressure regulator assemblies designed for systems where separate lubrication is managed externally.

Filter Series: Dedicated air filters designed to remove moisture, oil, and particulates, ensuring clean compressed air supply.

Pressure Regulator: Precision regulators to maintain consistent output pressure, protecting pneumatic equipment and processes.

Lubricator Series: Units that provide precise lubrication by injecting a controlled mist of oil into the compressed air, extending pneumatic tool life.

These product series are engineered for easy integration, durability, and superior performance across Chennai, Tamil Nadu, and all over India.

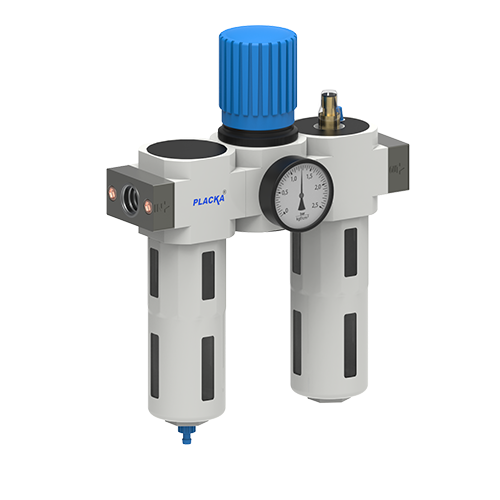

Introduction to Air Filter Regulator Lubricator (MIDI/MINI/MAXI)

Placka Instruments Pvt. Ltd., a renowned Indian manufacturer and supplier of pneumatic control devices, proudly presents the Air Filter Regulator Lubricator (MIDI/MINI/MAXI) series—an integrated air treatment unit combining filtration, pressure regulation, and lubrication. Engineered to optimize compressed air quality and ensure peak performance of pneumatic tools and systems, this modular assembly provides all-in-one air preparation tailored to diverse industrial applications across Chennai, Tamil Nadu, and all over India.

This compact yet powerful unit is available in three sizes—MIDI, MINI, and MAXI—to meet varying flow requirements and system capacities. Whether you’re operating a small workshop or a large production line, Placka’s Air Filter Regulator Lubricator (AFRL) ensures reliable, clean, and lubricated air supply for smooth and efficient pneumatic operations.

Combined Filter + Regulator + Lubricator for complete air treatment

Available in MIDI, MINI, and MAXI sizes to suit different air flow needs

Designed for easy installation and maintenance across Indian industries

Robust construction suitable for harsh environments in Chennai and beyond

Supported with expert technical service across Tamil Nadu and India

Understanding the Importance of Filter Regulator Lubricator Units

In Indian industries such as automotive manufacturing in Chennai, pharmaceuticals in Tamil Nadu, and heavy engineering across India, pneumatic tools rely heavily on clean, stable, and lubricated compressed air for longevity and performance. The Filter Regulator Lubricator (FRL) unit plays a crucial role by performing three essential air treatment functions: filtration removes dust, moisture, oil particles, and other contaminants; regulation maintains consistent air pressure within safe operational limits; and lubrication adds a fine mist of oil to reduce friction and wear inside pneumatic tools.

Without proper air preparation, contaminants can cause corrosion, blockages, and premature failure of pneumatic equipment—leading to costly downtime and repairs. Placka’s AFRL units guarantee optimal air quality and lubrication, extending equipment life and reducing maintenance demands in Indian industrial setups.

Construction and Material Excellence for Indian Conditions

Placka Instruments designs its AFRL units with premium materials selected for durability in diverse Indian environments—from humid coastal zones like Chennai to dusty inland factories in Tamil Nadu. The housing is typically manufactured from corrosion-resistant aluminum alloy, while bowls may be clear polycarbonate or metal for enhanced durability and easy inspection.

Corrosion-resistant aluminum alloy body suitable for Indian climates

Transparent polycarbonate or metal bowls for easy visual monitoring

Precision-machined components for leak-proof and stable performance

Durable filter elements to withstand dust and particulate load

Adjustable lubricator for tailored oil delivery

Key Functional Features of MIDI, MINI, and MAXI Series

Placka’s Air Filter Regulator Lubricator units come in three sizes to match different flow capacities and pneumatic system requirements:

MINI Series: Compact size ideal for small pneumatic tools and light industrial applications

MIDI Series: Medium capacity suited for medium-sized manufacturing lines and workshops

MAXI Series: High flow rate for large-scale industrial plants and heavy-duty pneumatic machinery

Modular design for flexible system integration

Clear bowls and sight glasses for visual inspection

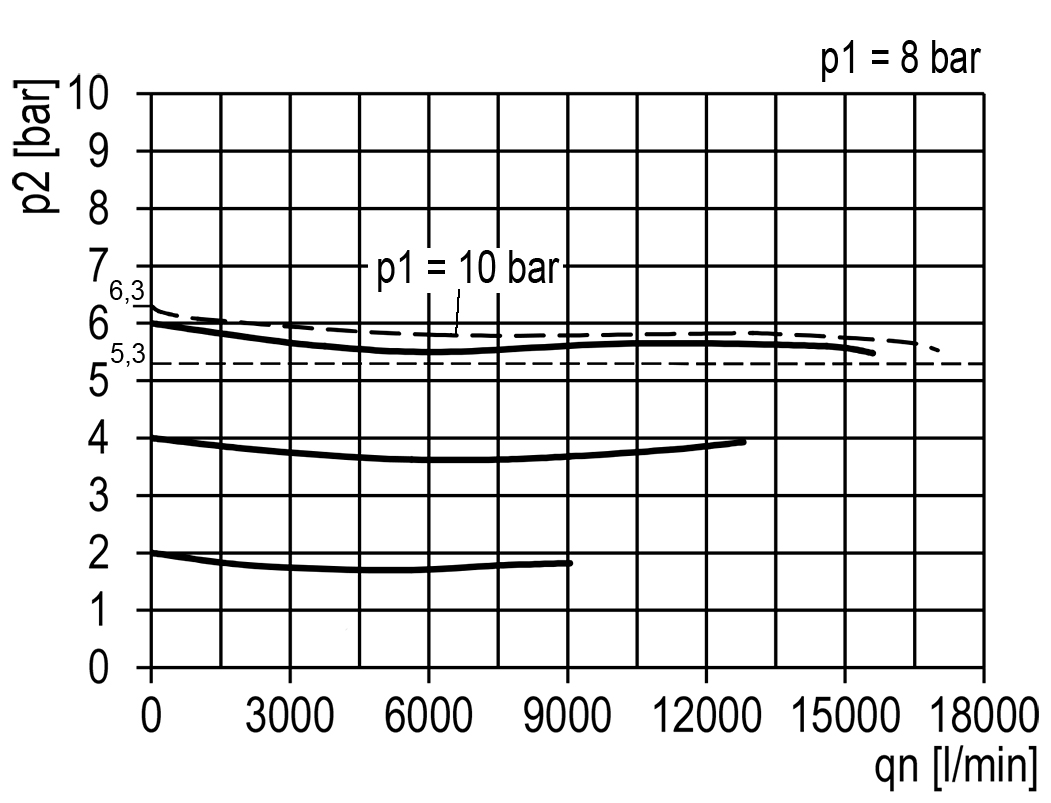

Performance Specifications That Meet Indian Industrial Standards

Maximum operating pressure: 16 bar

Regulated output pressure: 0.5 to 12 bar

Filtration rating: 5 micron particle removal

Adjustable lubrication feed for precise oil delivery

Operating temperature: 0°C to 60°C

Wide-Ranging Applications Across Indian Industries

Automotive Manufacturing (Chennai): Powers pneumatic assembly lines, spray painting, and tooling with clean, lubricated air

Food & Beverage Processing: Ensures hygienic air supply with consistent pressure and minimal contamination risk

Pharmaceutical Industry: Supports sterile production environments with controlled, filtered, and lubricated air

Textile Industry: Maintains smooth operation of pneumatic looms and machinery

General Manufacturing: Improves operational efficiency and tool life across SMEs and large factories

Quality Assurance and Compliance for Reliability

All Placka AFRL units are produced in compliance with ISO 9001:2015 quality standards, assuring high reliability and safety. Each unit undergoes rigorous quality control procedures, including pressure testing, leak detection, and filtration efficiency validation.

Placka’s commitment to quality makes it a preferred supplier across Indian industrial regions such as Chennai and Tamil Nadu, trusted for durable pneumatic components that deliver long-term performance.

Installation and Maintenance Ease for Indian Factories

Designed for straightforward installation, Placka’s AFRL units feature standardized connection ports compatible with common Indian pneumatic fittings. Maintenance is simplified through modular components—filter elements and lubricator oil reservoirs can be replaced or refilled quickly to minimize downtime.

The transparent bowls allow visual monitoring of contamination and condensate levels, enabling predictive maintenance and avoiding unexpected failures—a critical advantage for industries in Chennai, Tamil Nadu, and across India.

Advantages of Choosing Placka AFRL Units

Space-saving all-in-one air preparation in a compact design

Reduced installation and maintenance complexity

Optimized air quality and tool protection with precise filtration, pressure regulation, and lubrication

Durable construction tailored for Indian environmental challenges

Extensive after-sales technical support in Chennai, Tamil Nadu, and India

Why Choose Placka Instruments Pvt. Ltd.?

With over 50 years of expertise, Placka Instruments Pvt. Ltd. stands as a leading Indian manufacturer and supplier of pneumatic solutions. Our Air Filter Regulator Lubricator (MIDI/MINI/MAXI) units combine advanced engineering, quality materials, and practical design to deliver trusted air treatment solutions across India.

We serve customers throughout Chennai, Tamil Nadu, and all industrial regions of India, providing custom solutions, prompt support, and superior product reliability. When it comes to pneumatic air preparation, Placka Instruments is your trusted partner for excellence.

Deliver clean, stable, and perfectly lubricated compressed air across Chennai, Tamil Nadu, and India with Placka Instruments’ Air Filter Regulator Lubricator series — the all-in-one pneumatic solution that ensures efficiency and longevity.