Introduction to the Air Filter Regulator with Transparent Bowl

Placka Instruments Pvt. Ltd., a leading Indian manufacturer of pneumatic control devices, presents the Air Filter Regulator with Transparent Bowl—an essential component engineered to deliver clean, regulated compressed air for optimal pneumatic system performance. Designed with a transparent polycarbonate bowl for easy visual monitoring, this unit combines efficient air filtration and precise pressure regulation in a compact, durable package.

Widely trusted by manufacturers across Chennai, Tamil Nadu, and all over India, this air filter regulator ensures contaminant-free air supply by removing moisture, dust, oil aerosols, and particulates from compressed air systems. Maintaining clean, stable air pressure safeguards pneumatic tools, actuators, and production line equipment from damage and reduces costly downtime.

Whether used in automotive workshops, food processing plants, or pharmaceutical facilities, the transparent bowl design allows operators to inspect filter conditions quickly without dismantling the unit—streamlining maintenance and boosting productivity.

Integrated air filter and pressure regulator with transparent bowl

Efficient removal of moisture, oil, and particulates from compressed air

Visual monitoring of filter element and bowl condition for proactive maintenance

Robust construction suited for Indian industrial environments

Widely supplied and supported across Chennai, Tamil Nadu, and India

Importance of Air Filter Regulators in Industrial Compressed Air Systems

In India’s rapidly growing manufacturing sectors, especially in industrial hubs like Chennai and Tamil Nadu, maintaining high-quality compressed air is critical. Pneumatic systems depend on clean, dry, and stable air for reliable operation. Contaminants such as water droplets, oil mist, and dust particles can cause significant damage, reducing equipment lifespan and leading to costly breakdowns.

Placka’s Air Filter Regulator with Transparent Bowl plays a vital role by filtering out these contaminants while regulating pressure to desired levels. This dual-function ensures pneumatic tools and machinery operate efficiently with minimal wear and tear, increasing productivity and lowering maintenance costs across industries such as automotive, food & beverage, pharmaceuticals, and textiles.

Real-time visibility into the filter bowl condition helps Indian operators anticipate filter replacements before performance deteriorates, minimizing unplanned downtime and optimizing maintenance schedules.

Protect pneumatic equipment from harmful contaminants

Ensure consistent air pressure for smooth system operation

Facilitate timely maintenance through visual filter monitoring

Reduce operational costs by preventing premature equipment failure

Enhance overall efficiency of compressed air systems

Durable Construction Tailored for Indian Industrial Conditions

Designed with the challenging conditions of Indian manufacturing environments in mind, Placka’s air filter regulator features a rugged aluminum or metal body paired with a high-strength transparent polycarbonate bowl. This combination provides corrosion resistance, impact resistance, and long service life—even in dusty, humid, or hot factory floors found in regions like Chennai and Tamil Nadu.

The transparent bowl allows easy inspection of collected moisture and debris, eliminating guesswork during maintenance. It also incorporates a manual or automatic drain valve to remove accumulated condensate, preventing moisture from entering sensitive pneumatic components.

The unit’s precision-machined internal components ensure leak-tight performance and stable pressure control, maintaining high air quality and protecting costly downstream equipment.

Corrosion-resistant aluminum body for durability in Indian industries

Transparent polycarbonate bowl for clear visual inspection

Impact-resistant design to withstand factory floor conditions

Efficient condensate drainage options to maintain dry air supply

Leak-proof internal sealing for reliable, consistent performance

User-Friendly Features for Efficient Operation and Maintenance

Ease of use is critical in India’s fast-paced industrial environments, where minimizing downtime is key. Placka’s air filter regulator includes an ergonomic pressure adjustment knob for precise, tool-free tuning of output pressure. The integrated pressure gauge provides accurate, real-time feedback, enabling operators to maintain optimal settings effortlessly.

The transparent bowl simplifies routine maintenance, allowing quick identification of filter clogging or condensate build-up without interrupting operations. Replacement of filter elements and servicing of the bowl drain are straightforward tasks, designed to be completed swiftly by maintenance teams across factories in Chennai, Tamil Nadu, and beyond.

Compact and lightweight, the unit fits neatly into existing pneumatic setups with standard connection sizes, facilitating easy upgrades or new installations.

Tool-free, ergonomic pressure adjustment knob

Clear pressure gauge for easy monitoring

Transparent bowl for instant visual filter and condensate check

Quick-access bowl drain valve for efficient moisture removal

Compact design with universal connection sizes for easy installation

Superior Performance Specifications

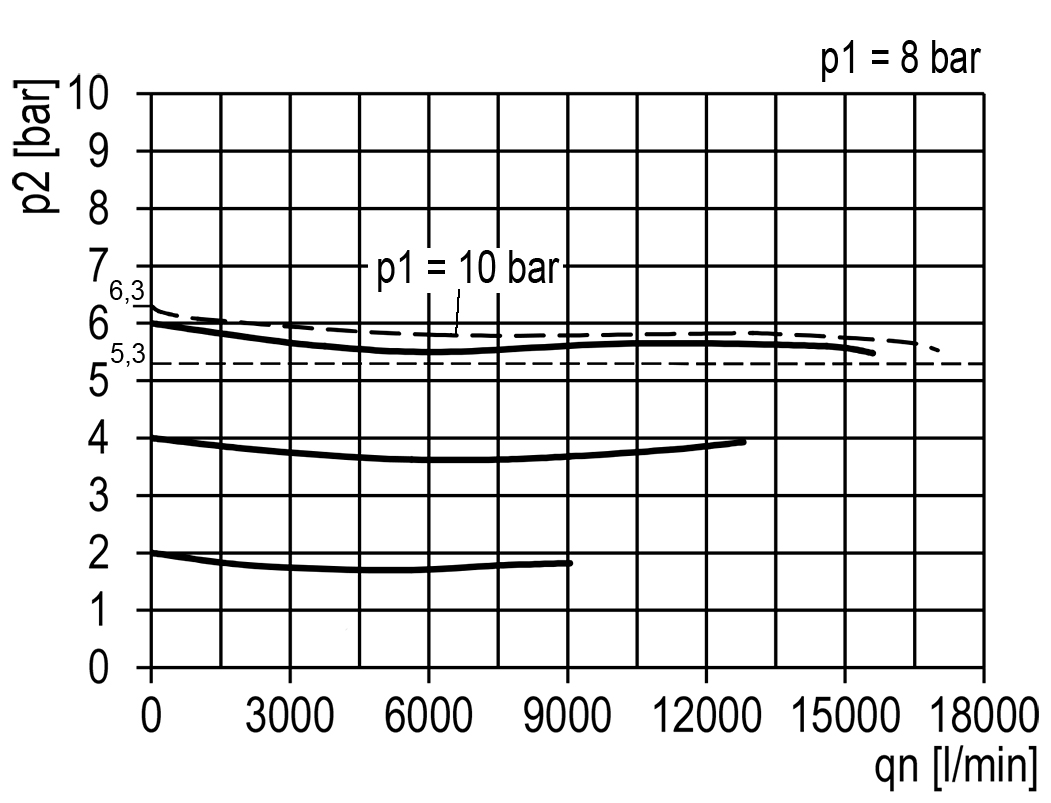

Placka’s Air Filter Regulator with Transparent Bowl delivers reliable pressure regulation within the range of 0.5 to 12 bar and operates effectively under inlet pressures up to 16 bar. The filter element captures particles down to 5 microns, ensuring clean, contaminant-free air supply.

Its operating temperature range from 0°C to 60°C suits the wide climatic variations experienced across India, from humid coastal regions like Chennai to drier inland areas of Tamil Nadu. The robust design withstands mechanical vibrations common in industrial environments, delivering consistent, stable performance.

The unit’s precise pressure regulation ensures pneumatic systems operate within specified tolerances, optimizing tool performance and reducing air wastage.

Maximum operating pressure: 16 bar

Adjustable output pressure: 0.5 to 12 bar

Filtration efficiency: 5 micron particle removal

Operating temperature: 0°C to 60°C

Vibration-resistant for industrial applications

Applications Across Diverse Indian Industries

Placka’s air filter regulator with transparent bowl is widely employed across various sectors in India due to its versatility and reliability:

- Automotive Workshops (Chennai): Ensures clean, regulated air for spray painting, assembly tools, and tire inflation systems.

- Food & Beverage (Tamil Nadu): Supports hygienic air delivery for processing and packaging lines.

- Pharmaceutical Manufacturing: Provides contaminant-free air to maintain sterile environments and equipment function.

- Textile Industry: Powers pneumatic looms and dyeing equipment with consistent air quality.

- Chemical Processing: Protects sensitive pneumatic instruments in corrosive atmospheres.

- General Manufacturing: Used extensively across SMEs and large factories throughout India.

These applications highlight the product’s critical role in maintaining operational efficiency and compliance with industry standards.

Compliance and Quality Assurance

Placka Instruments Pvt. Ltd. manufactures all air filter regulators in compliance with ISO 9001:2015 quality standards, ensuring reliable product performance and safety. Each unit undergoes rigorous testing for pressure accuracy, leak tightness, and filtration efficiency before shipment.

These stringent quality controls make Placka a trusted supplier for industries throughout Chennai, Tamil Nadu, and India’s broader manufacturing sector, delivering peace of mind alongside high performance.

ISO 9001:2015 certified manufacturing processes

Pressure integrity and leakage testing

Filtration efficiency validation to meet industrial standards

Material traceability for accountability

Continuous improvement programs for product innovation

Installation and Maintenance Made Easy for Indian Facilities

Placka’s air filter regulator is designed for fast, hassle-free installation with standard port sizes compatible with most Indian pneumatic systems. The modular design allows maintenance staff to replace filter elements and service the bowl drain quickly, minimizing system downtime.

The transparent bowl significantly reduces inspection time, empowering maintenance teams to schedule filter replacements proactively. This feature is especially valuable for factories in Chennai and Tamil Nadu, where production uptime directly impacts profitability.

Comprehensive technical support and installation guidance are available locally, ensuring seamless integration into existing infrastructure.

Standardized connection sizes for plug-and-play installation

Modular design enabling quick servicing and part replacement

Transparent bowl for simple, non-invasive condition monitoring

Reduced downtime with proactive maintenance alerts

Local technical support across Chennai, Tamil Nadu, and India

Advantages Over Conventional Air Filter Regulators

Placka’s Air Filter Regulator with Transparent Bowl offers several advantages over traditional units without visual monitoring:

Enables real-time filter status checks without disassembly

Prevents premature filter clogging-related failures

Reduces maintenance costs by optimizing service intervals

Improves operational safety by ensuring consistent air quality

Combines robust Indian-made construction with global-quality standards

Why Choose Placka Instruments Pvt. Ltd. for Your Air Filter Regulator Needs?

With over 50 years of manufacturing experience, Placka Instruments Pvt. Ltd. is a trusted Indian manufacturer dedicated to delivering superior pneumatic solutions. Our Air Filter Regulator with Transparent Bowl is engineered to withstand India’s unique industrial conditions while providing reliable, precision air filtration and regulation.

We serve clients throughout Chennai, Tamil Nadu, and all over India, offering customized solutions, expert technical support, and timely after-sales service. Partnering with Placka means investing in quality, durability, and performance tailored to India’s manufacturing ecosystem.

"For clean, stable, and visually monitored air pressure regulation trusted across Chennai, Tamil Nadu, and India—choose Placka Instruments Pvt. Ltd.’s Air Filter Regulator with Transparent Bowl for uncompromised pneumatic system performance."