Introduction to Purge Rotameters

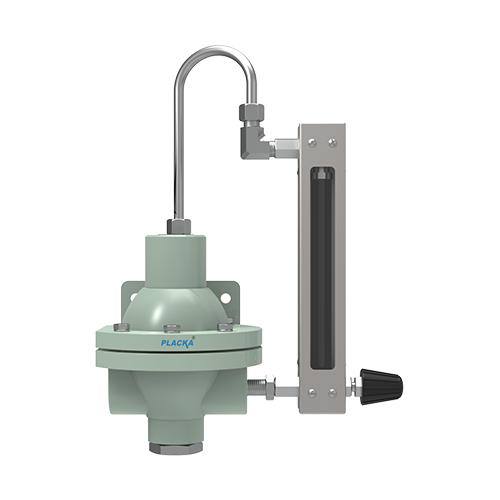

In today’s complex industrial landscape, precise flow measurement and control of purge gases is critical for maintaining safety, efficiency, and product quality. Placka Instruments Pvt. Ltd. proudly presents its range of Purge Rotameters, expertly engineered for robust and accurate flow monitoring in demanding industrial environments. With our manufacturing base and distribution network spanning India, including key industrial regions such as Tamil Nadu and Chennai, we ensure seamless supply and technical support nationwide.

Purge rotameters are essential flow meters used primarily for measuring and regulating the flow rate of purge gases such as nitrogen, air, or other inert gases. These devices play a pivotal role in processes requiring controlled atmospheres, contamination prevention, and safety purging, especially in sectors like chemical processing, pharmaceuticals, oil & gas, and food & beverage industries.

Crafted with the highest quality materials and precision engineering, Placka’s purge rotameters offer a combination of durability, accuracy, and corrosion resistance. Whether you operate in the humid climate of Chennai or the industrial corridors of Tamil Nadu, our rotameters deliver consistent, reliable performance that meets stringent industry standards.

Precise flow measurement for purge gases

Rugged construction for harsh industrial conditions

Applicable for gases and liquids in multiple sectors

Trusted supplier across India, Tamil Nadu, and Chennai

Backed by decades of engineering expertise

Placka’s Expertise: Trusted Purge Rotameter Manufacturer in India

Placka Instruments Pvt. Ltd. has been at the forefront of pneumatic and flow measurement innovation for over 50 years. We combine deep technical knowledge with state-of-the-art manufacturing to deliver Purge Rotameters that stand the test of time and rigorous industrial demands. Our commitment to quality and customer satisfaction makes us the preferred supplier for industries across India, particularly in manufacturing hubs like Tamil Nadu and Chennai.

Our expertise extends beyond product design to include comprehensive support — from custom flow meter solutions tailored to specific process requirements to post-sale technical assistance. This holistic approach ensures clients across India receive not just a product but a reliable, ongoing partnership.

Over five decades of industry experience

ISO-certified manufacturing processes

Customized flow meters for unique industrial needs

Pan-India supply chain including Tamil Nadu and Chennai

Dedicated technical and after-sales support

Superior Materials and Robust Construction for Industrial Durability

Industrial environments in India often expose equipment to harsh chemicals, moisture, high temperatures, and mechanical stresses. Placka’s Purge Rotameters are engineered to withstand these challenges through the use of premium-grade materials such as stainless steel and chemical-resistant alloys. These materials prevent corrosion, extend product lifespan, and ensure safety and hygiene, which are crucial for pharmaceutical and food processing industries prevalent in Tamil Nadu and Chennai.

Additionally, the precision-engineered float and tapered tube design ensure accurate, repeatable readings even under fluctuating pressure and temperature conditions typical in Indian industrial setups. Our rotameters’ rugged construction reduces downtime and maintenance costs by providing stable performance in demanding environments.

Stainless steel body for maximum corrosion resistance

Chemical-resistant internal components

High-temperature and pressure tolerance

Durable float design for accurate readings

Robust sealing to prevent leaks

Key Features and Functional Benefits of Purge Rotameters

Placka’s Purge Rotameters integrate a host of features designed to enhance usability, accuracy, and reliability:

Clear Graduated Scale for instant visual confirmation of flow rates

Precision Float made from corrosion-resistant materials

Adjustable Flow Control with integrated valves

Compact and Modular Design for tight spaces

Maintenance-Friendly design for easy cleaning and calibration

Functional Benefits:

Reliable and precise flow control

Real-time visual monitoring

Easy flow adjustment

Suitable for diverse installation environments

Low maintenance for continuous operation

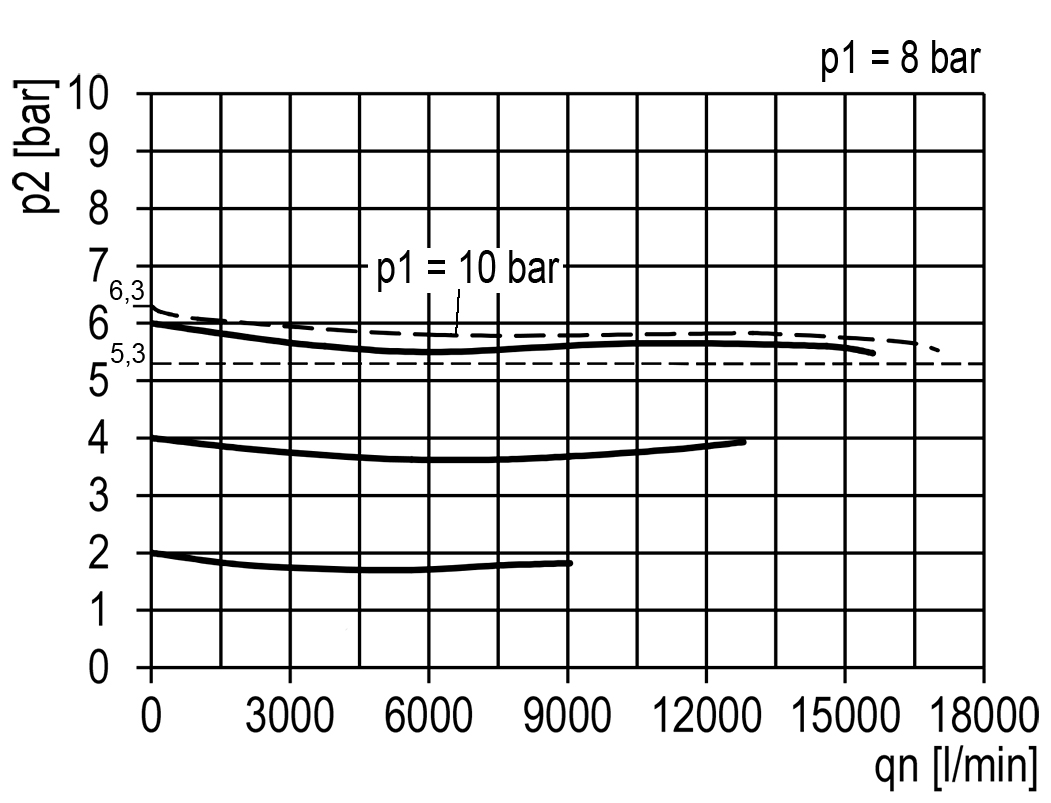

Performance Specifications Tailored for Indian Industries

Placka Purge Rotameters are designed for flexibility, accuracy, and durability. Their specifications reflect the requirements of Indian industries where varying environmental and operational conditions challenge equipment performance:

Flow Range suitable for low to high flow rates

Accuracy of +/- 2% full scale

High Pressure Rating to prevent failure and leakage

Wide Temperature Range for Indian climates

Material Compatibility with nitrogen, air, argon, and CO₂

Additional Performance Advantages:

Stable readings under pressure fluctuations

Resistant to clogging and contamination

Low flow resistance enhances efficiency

Complies with international and Indian industrial standards

Suitable for continuous and intermittent purge operations

Wide-Ranging Industrial Applications Across India

The versatility and reliability of Placka’s Purge Rotameters make them indispensable in multiple Indian industrial sectors:

Chemical Processing: Control of purge gases in reactors and pipelines to prevent contamination and hazardous conditions.

Pharmaceutical Manufacturing: Maintaining sterile environments with controlled inert gas flows during drug production, especially in Chennai’s pharma hubs.

Oil & Gas: Purge systems in refineries and pipelines to avoid explosive atmospheres, with equipment rugged enough to withstand coastal Tamil Nadu’s corrosive environment.

Food & Beverage: Ensuring hygiene and safety during packaging and storage through precise gas purging.

Power Plants & HVAC: Monitoring purge airflows in boilers and ventilation systems for optimal combustion and environmental control.

Serving Industrial Hubs:

Tamil Nadu chemical clusters

Chennai pharmaceutical manufacturing zones

Oil & gas refineries across India

Food processing plants nationwide

Power generation facilities in industrial zones

Quality Assurance, Certifications, and Compliance

Placka Instruments Pvt. Ltd. maintains stringent quality control protocols to ensure every Purge Rotameter meets global standards and client expectations. Manufactured in ISO 9001:2015 certified facilities, our rotameters undergo rigorous testing for flow accuracy, pressure resistance, and leak-tightness.

These quality benchmarks are critical for Indian industries bound by safety and regulatory requirements. Our products also comply with EIL and other certification standards, making them suitable for critical applications across Tamil Nadu, Chennai, and the wider Indian market.

ISO 9001:2015 certified manufacturing

Tested for flow accuracy and repeatability

Pressure and leak-proof validated

Complies with Indian safety and industrial norms

Multi-stage quality assurance for every unit

Easy Installation and Maintenance for Indian Industrial Needs

Recognizing the operational challenges faced by Indian industries, Placka designs its Purge Rotameters for quick installation and hassle-free maintenance. Standardized connection sizes allow integration with existing piping systems in plants across Tamil Nadu and Chennai, minimizing downtime during upgrades or replacements.

The modular construction means components like floats and tubes can be serviced or replaced without dismantling the entire assembly, a critical advantage in high-throughput Indian manufacturing plants. Additionally, the stainless steel surfaces resist fouling and corrosion, simplifying cleaning routines especially important in food and pharmaceutical sectors.

Universal fittings for quick compatibility

Modular parts for efficient servicing

Corrosion-resistant materials for hygiene

Minimal downtime during maintenance

Designed for Indian factory environments

Advantages Over Other Flow Measurement Technologies

While electronic and digital flow meters offer advanced features, Purge Rotameters provide unmatched simplicity, reliability, and cost-effectiveness for many industrial purge applications, especially in India’s diverse industrial climate. Their mechanical nature means fewer failure points and easier repairs, reducing total cost of ownership.

Compared to plastic flow meters, our stainless steel rotameters withstand India’s challenging temperature extremes and chemical exposure. Unlike orifice plates or differential pressure meters, they provide direct visual flow readings without complex instrumentation.

Economical and low maintenance

Robust stainless steel construction

Easy calibration and real-time reading

Resistant to power supply interruptions

Proven durability in Indian industries

Why Placka Instruments Pvt. Ltd. is Your Go-To Purge Rotameter Supplier in India

Placka Instruments combines cutting-edge engineering, premium materials, and decades of expertise to produce Purge Rotameters that meet the diverse needs of Indian industries. We provide a full suite of services — from product customization and rapid delivery to technical training and after-sales support — ensuring seamless operation from installation through lifecycle.

Our strong presence across India, including Tamil Nadu and Chennai, means fast response times and localized support, helping industries optimize their purge gas flow control processes.

50+ years of trusted industry leadership

Customization to fit exact client needs

Pan-India presence with Tamil Nadu and Chennai focus

Dedicated customer and technical support teams

Continuous innovation for future-ready solutions

“When precise gas flow control and industrial durability matter most, Placka Instruments’ Purge Rotameters deliver unmatched performance and peace of mind across India’s toughest environments.”